On-load Tap Changers (OLTC or LTC)

What are on-load tap changers?

On-load tap changers (OLTCs) are crucial components in the power system due to their purpose of maintaining the voltage output desired. OLTCs perform frequent operations to maintain these voltages. When maintained properly and operated within design limits, these components should provide many years of reliable service.

Types of on-load tap changers

The type of OLTC should influence the plan for inspections and online/out-of-service testing. There are two distinct types of OLTCs. First, bolt-on or welded-on OLTCs fit onto the sidewall of a transformer. Second, in-tank type OLTCs install inside the tank and suspend from the cover. Both designs can include arcing in oil-type diverter switches using resistors, series reactors or vacuum interrupters. These various components are designed for installation inside the tank and to be suspended from the cover.

What are the failure modes of on-load tap changers?

The OLTC is the major mechanical moving device on a transformer. As with any mechanical device, movement equates to the wear of components over time and frequency of operation. The OLTC failure modes can be the same or segregated, depending on the type of testing or monitoring performed. Some failure modes can be detected with sensors and systems. Others can only be determined with a combination of sensors and laboratory testing (oil, for example). To learn more about various diagnostic methods, read this article from Transformer Technology Magazine.

Online Monitoring for On-load Tap Changers

Why online monitoring?

According to a recent CIGRE Transformer Reliability Survey, on load tap changers (OLTC) have one of the highest failure rates of any transformer component! If an OLTC fails, a transformer cannot regulate voltage. There are still many OLTCs in service today based on older technology. They are much more susceptible to significant wear and tear on critical elements. This wear is frequently the cause of misoperation or even unexpected failures when not properly maintained.

How to Monitor On-load Tap Changers?

Implementing online monitoring for an OLTC is relatively easy. There is a mechanical operations counter on every OLTC. It records an event (cumulative) every time the OLTC operates. The tap position indicator on every OLTC is a mechanical device. It provides the current tap position and the ‘range of movement’ the mechanism has operated. The movement is recorded using resettable drag hands on the indicator.

By adding a remote tap position sensor, a monitor will track and trend the total operations, number of operations at each position, and the I2T to provide an idea of contact wear. The monitoring system can provide control if desired. It can also monitor the frequency of reversing switch operations. In other words, the time since it last moved through that position to “wipe the contacts”.

Key Parameters for OLTC Monitoring

- OLTC Tap Position Tracking

- OLTC Tap Changer Differential Temperature

- OLTC Motor Energy+ Tracking

- OLTC Contact Wear

- Reversing Switch Operation

- Traditional DGA and Physical Analysis (Lab) of Oil in External Compartment

- DGA Ratios (Duval Triangle) of Oil in External Compartment

- and more

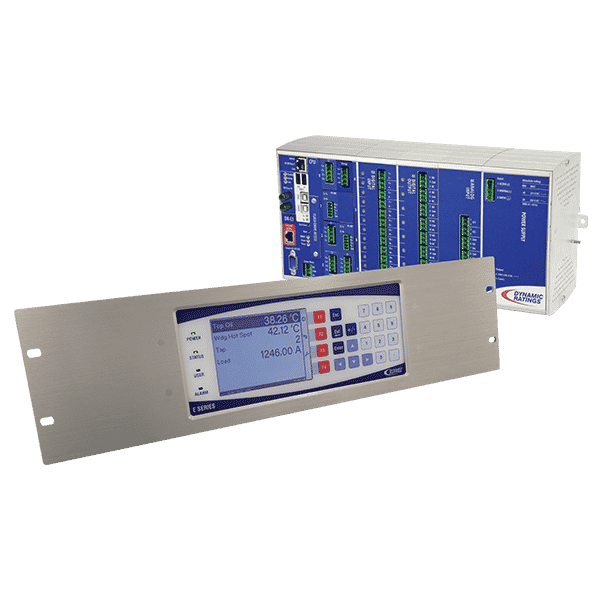

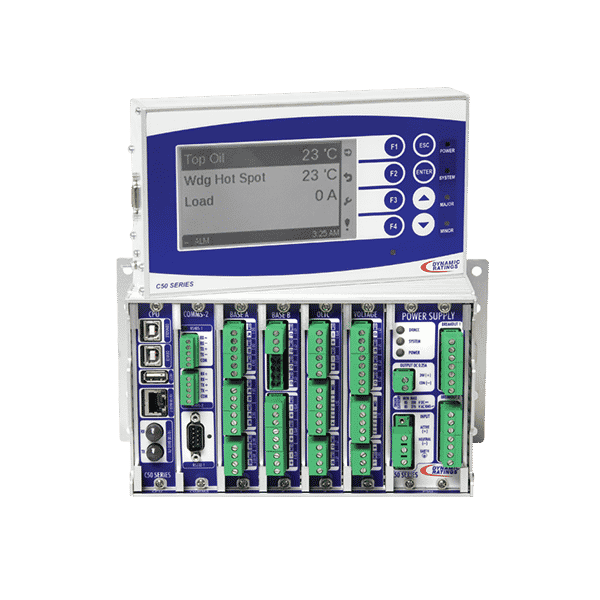

Introducing OLTC Monitors

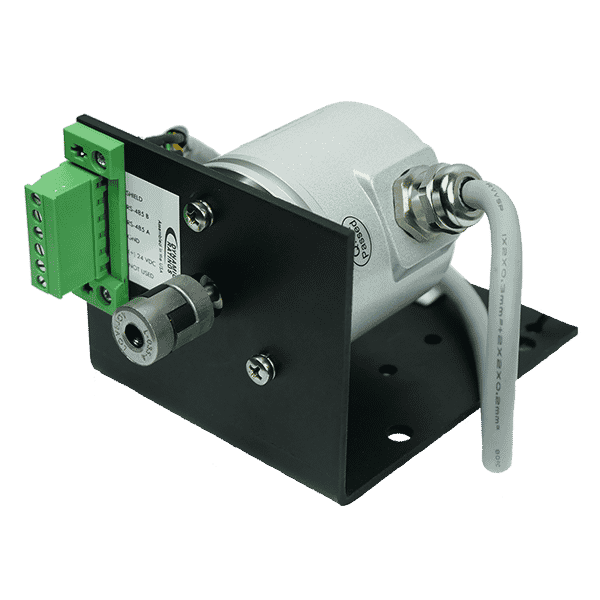

Tap Position Sensor

The Tap Position Sensor is a robust single solution that connects directly to the tap changer on your transformer, using an industry-standard optical encoder to detect the position of the tap changer.The backlit LCD display indicates the tap position of the load tap changer. The position can be relayed via an RS485 Modbus Connection or a 4-20mA analog loop.